Sheets for Thermoforming

As growing population across the world drives urbanisation and global connectivity, the need for electronics is at an all-time high. Work from home and online schooling due to COVID-19 pandemic has further pushed demand for smartphones, laptops, tablets and computing devices. This is driving an increased need for safe, reliable, lightweight easy to handle packaging material that can keep electronic components safe from Electro Static Discharge (ESD). As supply chain disruptions are pushing manufacturing from China and other Asian countries to India, there is a need for local availability of ESD safe packaging.

ESD is a sudden flow of electricity between electrically charged objects, typically caused by build-up of static charge by contact, electrical short or die-electric breakdown. Static generated through ESD can be as high as 20,000 to 45,000 volts under specific conditions of humidity in the air, object material, type of contact etc, whereas a low charge of 25 volts alone can damage critical microelectronic parts and components. Hence, managing ESD is very critical, to limit damage caused to components, loss of data, and avoid fire / explosions.

ESD materials used in packaging are designed to reduce this build-up of static electricity.

There are three types of ESD

Anti-static Materials

Anti-static materials prevent static build-up by tribo-charging. These materials are most commonly used across electronic packaging, cosmetics and food applications. Typically, surface resistivity of anti-static materials is in the range of 1010 to 1012 ohm/sq. and supress initial electrostatic charges.

Dissipative Materials

Anti-static materials prevent static build-up by tribo-charging. These materials are most commonly used across electronic packaging, cosmetics and food applications. Typically, surface resistivity of anti-static materials is in the range of 1010 to 1012 ohm/sq. and supress initial electrostatic charges.

Conductive Materials

Conductive materials are designed to provide least resistance, allowing electricity to flow easily through the material and pass onto other conductive object or ground in contact. Widely used for packaging and storage of consumer and automotive electronics, medical devices, and aerospace components. Surface resistivity of conductive materials is in the range of 103 to 106 ohms/sq. with no initial charge.

Zylog’s Composites Division manufactures a range of ESD sheets providing anti-static, dissipative and conductive performance, for thin and thick gauge thermoformed packaging.

Range of Grades

Zylog’s grades are designed keeping in mind application performance criteria, material cost, environmental conditions, storage, life expectancy, product sensitivity, aesthetics, type of packaging – one time v/s re-usable, and type of packaging. Our range of PP, PE and TPO (Flexible and Rigid) sheets, provide excellent balance of mechanical, physical and shielding properties for thermoformed packaging applications.

With robust quality checks, including surface resistivity and volume resistivity tests, we measure resistance and provide material performance conformity, thus assuring our customers of meeting requirements.

Range of Applications across Packaging & Material Handling

Material Handling

- Component Transit Trays

- Pallets

- Layer Pads

- Internal Dividers

- Conductive / ESD / Anti Static Trays

Packaging For Transportation

- General Industrial Boards

- Precise Machined Component Trays

- Casting & Forgings Item Trays

- Furniture Packaging

- White Goods Packaging

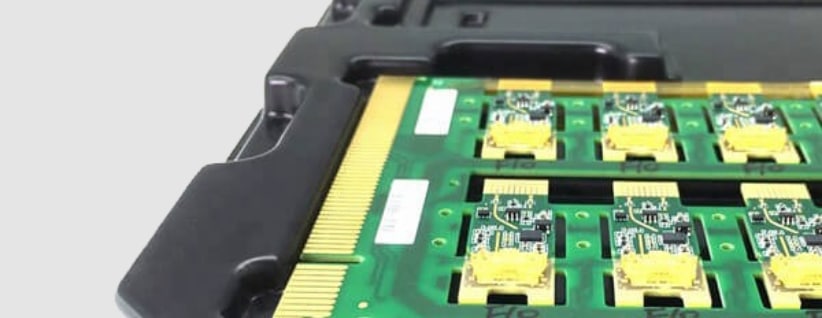

- Printed Circuit Boards Packaging

- Electronics Packaging

About Zylog

Established in 1984, Zylog is India’s leading TPE company, manufacturing a wide range of TPV (PP/EDPM), TPE (SBC), TPO and other blends and alloys, servicing applications across automotive, medical and healthcare, wire and cable, electrical / electronics, appliances, building construction, agriculture and animal management and other industrial uses.

The Composites Division manufactures a wide range of TPO, TPE and TPV sheets and laminates in widths of 2 meters for applications in automotive, packaging, material handling, poultry, building construction and industrial applications. Besides sheet extrusion, the division also manufactures thick gauge thermoformed components with capabilities to produce parts as big as 3 mtr X 2 mtr.

With 2 IATF 16949 manufacturing facilities across India, Zylog services domestic market as well as exports across Europe, Asia, Middle East and Africa (www.zylogelastocomp.com).